Today’s electrical systems are complex and high performance. Excessive heat relative to the entire system can be a sign of potential problems. These higher temperatures often indicated loose or faulty connections, improper wiring installation, ground faults, short circuits and other common problems in electric equipment. It is often difficult to determine if there is a ticking time bomb within your electrical system simply from a visual inspection. With the help of Certified Infrared and their top-of-the-line equipment and expertise, you can pinpoint and repair electrical problems before they fail. This will ultimately reduce or eliminate your operational downtown and keep your company on a profitable track. See this brief video on what thermal imaging is all about. Thermography Report for Sovereign Electric.

The goal of every electrical infrared (thermal) inspection is to survey designated electrical equipment in order to pinpoint defective components and elevated temperatures within your power distribution system. If unfound or untreated these thermal “hot spots” can cause- potential fire, explosion, or electrical service interruption threats.

Thermal hot spots are typically caused by unbalanced or overloaded electrical circuits, loose connections, or broken equipment. These conditions are often overlooked during routine evaluations of facilities and can result in the release of heat that will be visible only through infrared thermography detection services.

A typical electrical infrared survey can in a net a savings from $10,000 to $20,000, depending on the number and category of anomalies found. In addition to the direct financial savings, valuable time is saved by incorporating an annual infrared electrical survey into your PM program. Providing accurate information regarding the integrity of your electrical system’s components cuts down on maintenance time, prevents costly replacements and can eliminate unforeseen outages and downtime. An infrared (thermal) electrical inspection survey can help:

Our certified thermographers quickly and non-destructively pinpoint electrical and mechanical problems that cannot be seen with the naked eye, such as loose connections, faulty breakers, disconnects, overloaded circuits, imbalanced loads, weak motor windings and bearings, and much more. Detection of and imaging of thermal problems are done using modern thermography cameras. During the electrical infrared survey, our team will generally inspect the following equipment, but can provide inspection and imaging on any electrical or mechanical components according to your specification.

Sovereign Electric infrared reports are concise and to the point, making anomaly location easy to determine and facilitate repairs. Your report will include a detailed easy-to-read inspection report including:

A report sheet accompanies each problem which includes:

Each Electrical survey will be conducted with the latest technology in the industry and will be followed by a complete Electrical survey report similar to this report. Call today to setup your appointment. 856.552.0946 or email us at Info@sovereignelectric.net

Please enter Payment Details

Please enter amount to pay

Please enter an Invoice #

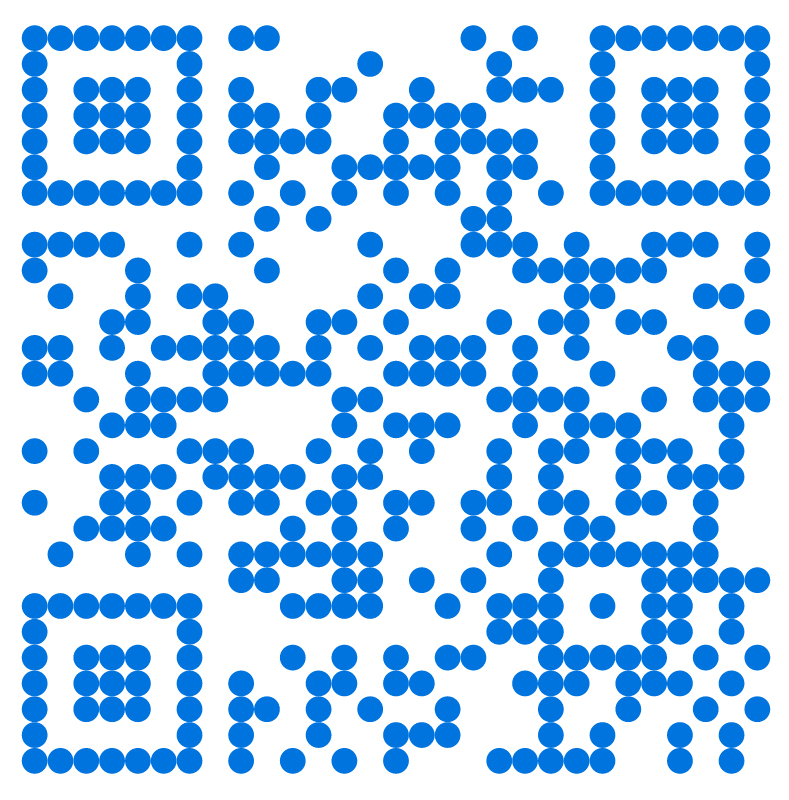

Scan to open Venmo and pay Sovereign Electric LLC